In an effort to aid engineers/architects with their commercial sanitary designs and ensure headache-free operation for end users, AWS/FujiClean have secured Health Department approval for certain minimum standards applicable to all FujiClean commercial designs.

Why are Minimum Commercial Standards Necessary?

FujiClean units, like all other I/A systems approved for use on Long Island, are designed to treat residential strength effluent. And while FujiClean units are plug-and-play replacements for conventional septic tanks and cesspools in a residential setting, commercial sanitary design is a different animal. Commercial waste streams are typically much more concentrated than residential waste streams, as commercial sanitary waste does not get the same amount of dilution that residential waste receives from showers, laundry use, etc. As a result, in order for I/A systems to reduce total nitrogen levels down to 19 mg/l – as required by Suffolk County – there are additional requirements for onsite commercial sanitary design that can vary depending on the type of use, as detailed in the FujiClean Commercial Design manual. While FujiClean’s commercial team may have additional design recommendations (e.g., flow equalization, additional treatment capacity, carbon feed, etc.), the newly-approved minimum commercial standards represent the components that FujiClean will (almost) always require for a commercial project

What is Included in FujiClean’s Minimum Commercial Standards?

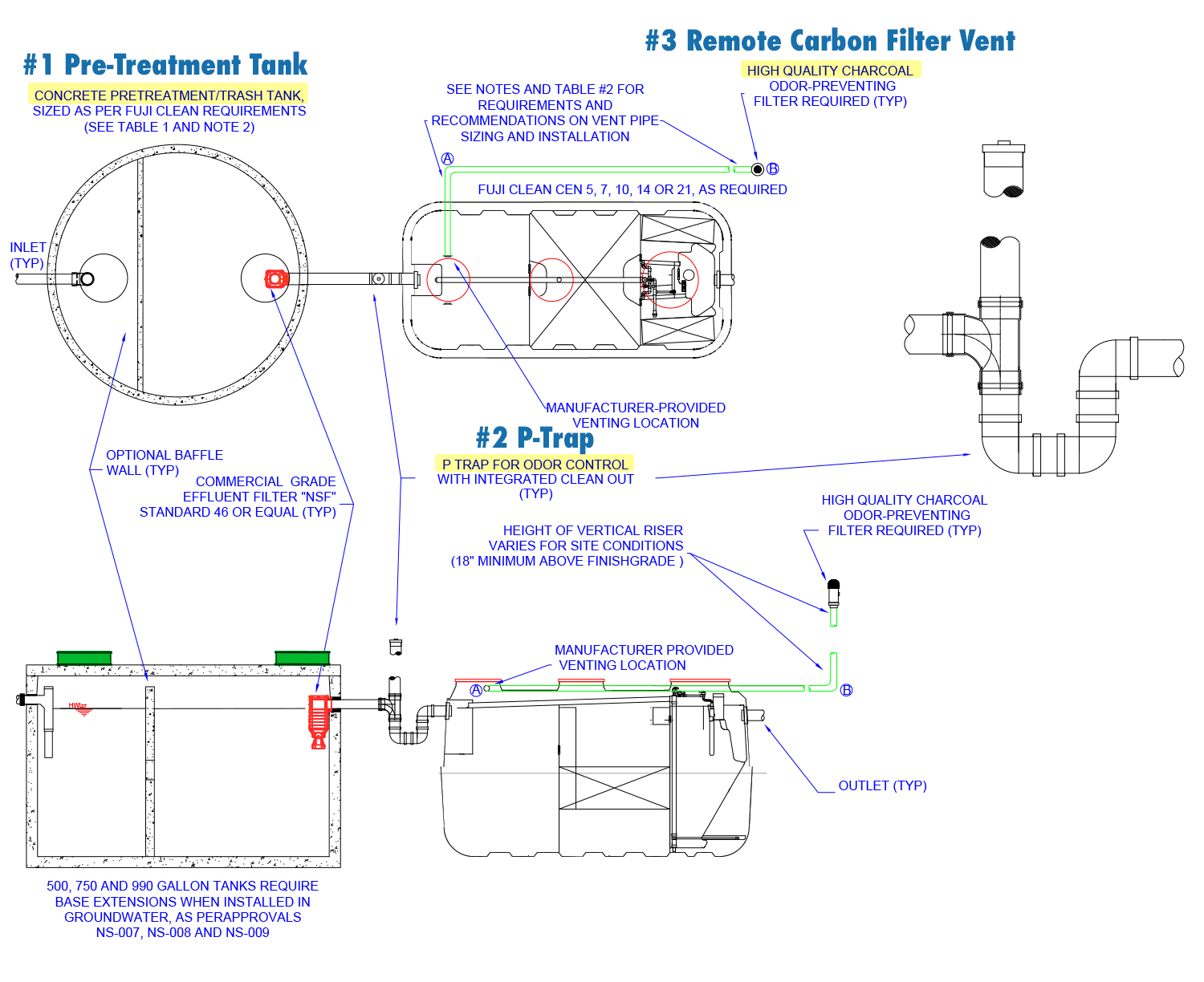

There are three primary components in FujiClean minimum commercial standards, each of which are relatively minor: a pre-treatment tank preceding the FujiClean unit, a p-trap between the FujiClean unit and the pre-treatment tank, and a remote carbon filter vent.

-

Pre-Treatment Tank

- A pre-treatment tank simply consists of a standard septic tank sized for ½ to 1 day flow that is installed between the building and the FujiClean unit. The purpose of the pre-treatment tank is twofold: (1) it serves as a trash trap to catch any garbage or inorganic material that tends to find its way into commercial waste streams before it can enter the treatment system; and (2) it provides the optimal retention time (i.e., 1/2 to 1 day) to reduce BOD levels by up to 30%, which dilutes the strength of the waste stream and brings it closer in line with the residential strength waste I/A systems are designed to treat.

-

P-Trap

- The inclusion of a p-trap between the pre-treatment tank and FujiClean unit prevents odors from escaping through the lids of the pre-treatment tank. The FujiClean system includes an air blower that sends a constant stream of air into the system that typically vents back up through the waste line and out of the building’s roof vent. Because the pre-treatment tank is filled with untreated wastewater, the air from the FujiClean blower can result in odors from the pre-treatment tank escaping through the lids. The p-trap prevents air from the Fuji blower from moving into the pre-treatment tank.

-

Remote Carbon Filter Vent

- FujiClean has always recommended the inclusion of a remote carbon filter vent for commercial projects, as they provide a secondary means of ventilation. However, with the new requirement of a p-trap, a remote carbon filter vent is now a must because the p-trap prevents the air from the FujiClean blower from venting through the building.

In recognition of the fact that there may be certain projects where these minimum commercial standards are not necessary (e.g., projects with extremely low flows), the Health Department has authorized FujiClean to waive these minimum standards on a case-by-case basis if the project designer provides a compelling rationale for doing so. If you think you have a project that qualifies for such an exemption, simply reach out to AWS and we will put you in touch with FujiClean’s commercial design team to review.

View The Minimum Commercial Design Requirements on our Resource page HERE